This is a fully integrated system for shredding, crushing, screening, and sorting scrap metal. It is designed for efficient recovery of ferrous metals, non-ferrous metals, and non-metallic materials.The Scrap Metal Shredding Crushing Sorting Line can be customized based on specific material types, capacity requirements, and environmental standards, making it ideal for various industrial recycling applications.

1. Material Feeding:

The raw materials are loaded onto a chain-type conveyor, which transports them steadily into the shredder.

2. Primary Shredding:

The shredder breaks the materials into large pieces, making them suitable for further processing.

3. Secondary Crushing:

The shredded materials are then transferred via conveyor to a hammer crusher, where they are crushed into smaller, uniform particles.

4. Dust Collection:

A dust collection system operates simultaneously to capture dust generated during the crushing process, ensuring a clean and environmentally friendly operation.

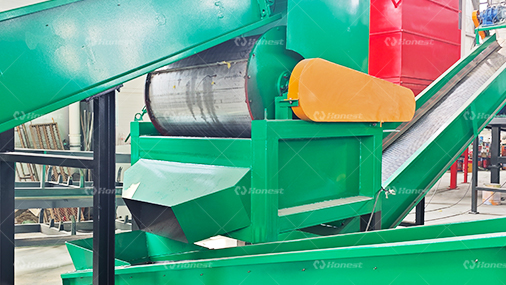

5. Magnetic Separation:

The crushed material passes through a magnetic separator, which removes ferrous metals (iron) from the material stream.

6. Rotary screen:

The remaining non-ferrous and plastic mixture is conveyed into a rotary screen, which separates the material into three different size categories, each discharged from a separate outlet.

7. Eddy Current Separation:

Each of the three size-based outputs is fed into a dedicated eddy current separator, which effectively separates non-ferrous metals (like aluminum and copper) from plastic.

Scrap Steel & Mixed Iron Crushing and Sorting Recycling Line

The scrap steel shredding line is an automated system for processing waste metals. It crushes and sorts scrap into high-quality furnace feedstock with a recovery rate over 95%. Capacity:10-50 tons per hour. ideal for large-scale recycling.

Examples of Recyclable Materials

Waste Stator,Rotor & Copper Coil Shredding & Sorting Recycling Line

Equipped with specialized shredders and multi-stage separation technology, the system efficiently separates copper from iron, plastics, and rubber, significantly increasing metal recovery rates. Pure copper granules (copper content >98%), ready for direct smelting.

Examples of Recyclable Materials

Scarp Aluminum Crushing and Sorting Recycling Line

Through crushing and separation processes, it efficiently separates aluminum from impurities, producing high-quality recycled raw materials that meet smelting requirements. The aluminum recovery rate reaches over 98%, with impurity content less than 2%.

Examples of Recyclable Materials

Scrap Steel Tailings Recycling Line

The scrap steel tailings recycling line begins by removing light waste from the feed. Iron is then separated and recycled, followed by the recovery of non-ferrous metals like copper and aluminum, and finally stainless steel. The remaining material consists of solid waste impurities.

Examples of Recyclable Materials

Through processes such as crushing and separation, these materials can be effectively sorted into iron, copper, aluminum, and non-metallic components, significantly improving recycling efficiency and resource utilization. Below are some examples of the output materials:

We implement a strict quality control process to guarantee peak performance of every machine.We own 40000 Square meters' workshops with 25+ sets machining equipment, including 15 sets CNC for precise parts manufacturing. From single units to full production lines, each machine undergoes comprehensive testing before shipment. Based on the recovery features of each machine, we design the most suitable recycling solution for your materials.

METAL CRUSHER

Utilizes a high-speed rotating hammer head to crush materials into smaller pieces through powerful impact force, ensuring efficient.

ZIGZAG SEPARATOR

Separates light and heavy materials based on their aerodynamic properties, enhancing sorting accuracy.

MAGNETIC SEPARATOR

During vibration screening, the magnetic roller efficiently removes iron-containing materials from the material flow.

ROTARY SCREEN

Classifies plastics and non-ferrous materials into three different size categories for precise sorting.

EDDY CURRENT SEPARATOR

Separates plastics from non-ferrous metals such as copper and aluminum, ensuring high recovery rates for valuable materials.

VIBRATING SCREEN

Uses vibration to classify and convey materials, improving sorting efficiency.

AIR SEPARATOR

Separates materials based on density differences using airflow technology.

PULSE DUST COLLECTOR

Collects dust generated during the shredding and sorting process, ensuring a clean working environment.

Honest is a leading manufacturer with 20 years of experience in recycling machinery, serving over 2,000 recyclers worldwide and providing one-stop recycling solutions. To ensure optimal machine per-formance, every unit-whether a single machine or a complete production line-is fully assembled and connected for testing before leaving our factory. We even purchase raw materials for trial runs, en- suring every component meets our production standards and delivers reliable, consistent results.

Welcome to visit Henan Honest website. If you want to learn more about our equipments, Contact us Now to find out what we can do for you next project!