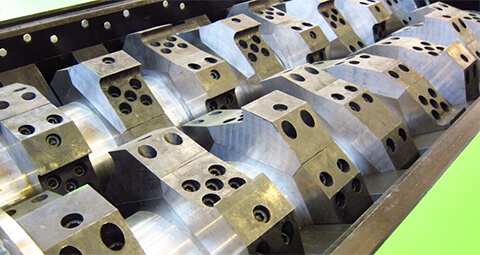

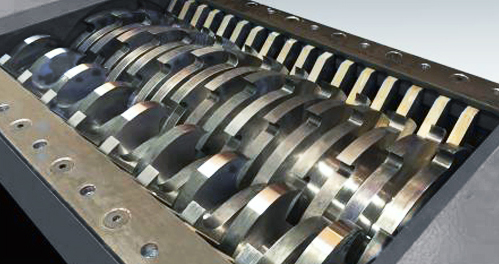

Double shaft shredder machine is the preprocessing equipment, the pre-sorted material to be chopped is fed into the two shafts whose rotors are moving slowly in opposite directions (therefore dust and noise free). The cutting discs are plugged on the shaft. This double shaft shredder machine is designed for longevity; The number of the knives or their width respectively determines the size of the output material.

Working process of two shaft shredder is controlled by an intelligent and innovative PLC. In case the industrial shredder machine is overloaded or foreign objects are in the cutting unit, the rotor stops and moves backward (return overload behaviour and reverse running to prevent overfeeding and protect against damage from foreign objects). The precisely serrated fixed knives make sure the material is shredded with a minimum of power. The fastened wiper element helps to avoid multiple turn coiling and raising of the material to be chopped.

Feed the material to the rotor which is setted a appropriate rotarty speed.

The material is shredder machineed by the rotor teeth.

Continued shredding and maximize the capacity.

Double shaft shredder machine (also known as two shaft shredder) is suitable for all sorts of industrial waste, metal sheet and plastic waste, production waste, binder, paper and cardboard boxes, electronic scrap, electric cables, metal sheet, food, food remains, biogenic waste, wood, glass, plastic waste, various containers for liquids, scrap clothes, leathers, shoes, fishing net, etc.

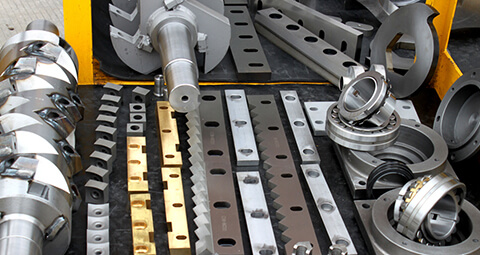

Blade materials include 9CrSi, Cr12MoV, SKD-II, D2, DC53, etc. It also can be customized.

Steel plate of crushing chamber is very thick, so very strong and durable, long service life.

We design shredder machine blades with different thickness for processing different raw materials.

The bearing pedestal adopts the split type, easy to maintain and replace the blade.

Welcome to visit Henan Honest website. If you want to learn more about our equipments, Contact us Now to find out what we can do for you next project!